1 Introduction

1.1 Background

Caprolactam is the monomer for the synthesis of nylon-6 and engineering plastics. Hydrorefining of caprolactam is an important process to get high purity caprolactam. In the process of hydrorefining of caprolactam in magnetically stabilized bed (MSB) reactor, hydrogen is dissolved in the caprolactam aqueous solution, then this hydrogen-containing caprolactam aqueous solution contacts with amorphous nickel alloy catalyst in the liquid-solid MSB reactor. The unsaturated impurities in caprolactam aqueous solution are saturated by hydrogenation. As a result, the quality of caprolactam is greatly improved.

1.2 Process description

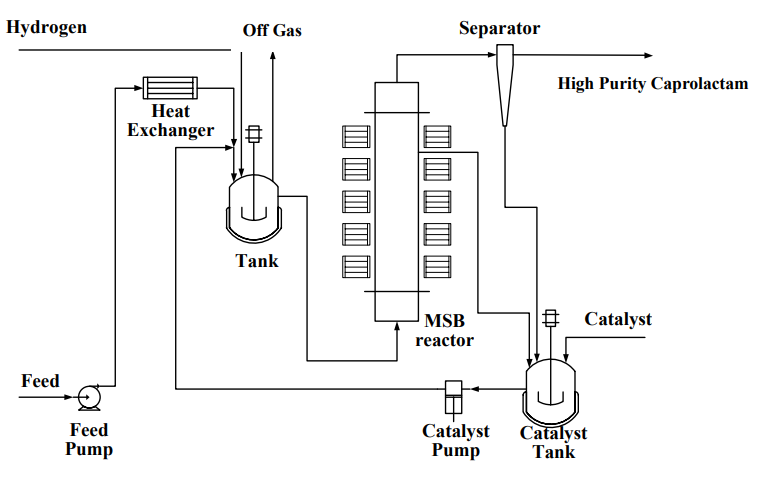

The MSB reactor process for hydrorefining of caprolactam mainly consists of 5 units including catalyst preparation, feedstock (caprolactam aqueous solution) preheating, hydrogen dissolution, hydrogenation reaction and catalyst separation (Fig 1). The preheated feedstock contacts with hydrogen in a mixer, in which hydrogen is dissolved in the feedstock, then this hydrogen-containing caprolactam aqueous solution is introduced into the MSB reactor which is equipped with amorphous nickel alloy catalyst. After hydrogenation reaction, the caprolactam aqueous solution is introduced into a cyclone hydraulic separator. After separation, the entrained catalyst can be recycled and the caprolactam aqueous solution is introduced into the following process.

1.3 Operating conditions

Reaction temperature: 50~100℃, Reaction pressure: 0.5 – 1.0 MPa, Liquid hourly space velocity (LHSV): 10 – 30 h-1, Magnetic field intensity: 24 – 48 kA/m.

2 Technical characteristics

2.1 Process characteristics

Compared to the traditional hydrorefining process of caprolactam in the batch reactor with Raney nickel catalyst, MSB hydrogenation refining process applies amorphous nickel catalyst with high hydrogenation activity and good magnetic properties.

The MSB reactor also combines the advantages of a fixed-bed and a fluidized-bed to strengthen the reaction process, enhancing the reaction. It facilitates an efficient removal of trace impurities by hydrogenation, and improves the quality of caprolactam products. The volume of the MSB reactor is reduced by 70%, and meanwhile the catalyst consumption is reduced by 70%.

Fig. 1 Flow scheme of MSB reactor process for hydrorefining of caprolactam.

2.2 Operation flexibility

This unit can operate stably within the range from 30% to 120% of the designed capacity, which shows an excellent operation flexibility of the technology.

2.3 Feed adaptability

This process is suitable for the hydrorefining of caprolactam aqueous solution with the concentration from 20% to 50%.

2.4 Performance

Through hydrogenation, the PAN value of the caprolactam aqueous solution reduces to ≤4 (ISO 8660:2002).

For the MSB reactor process, the catalyst consumption is less than 0.10 kg per ton caprolactam and the hydrogen consumption is less than 3.0 Nm3 per ton caprolactam.

2.5 Operation cycle

The operational cycle of the MSB unit for caprolactam hydrorefining is 2 – 3 years, which meets the requirements of the users.

3 Catalyst

3.1 Brief introduction

Amorphous nickel alloy catalyst (SRNA-4) is used as the hydrogenation catalyst. The catalyst particle diameter is 50 – 150 μm, the BET specific surface area is 110 – 150 m2/g and the bulk density is 1,800 – 2,200 kg/m3.

3.2 Technical characteristics

The lifetime of SRNA-4 catalyst used in the process of hydrorefining of caprolactam in MSB reactor is 3,500 hours. The catalyst can be replaced during operation. So regeneration of the catalyst is not required in this process.

4 Commercial applications

Six commercial MSB units have been set up so far. The largest capacity of these units is 100kt/a. All commercial MSB units are running smoothly. SINOPEC also achieved a PDP of MSB unit with capacity of 150 kt/a for licensing.