1. Introduction

1.1 Application

The SED process is an extractive distillation process using sulfolane and a co-solvent. The process can be used to recover high purity benzene or benzene toluene (BT) or benzene toluene and xylenes(BTX) from hydrocarbon mixtures such as hydrogenated pyrolysis gasoline, reformate or coke oven light oil.

1.2 Process Description

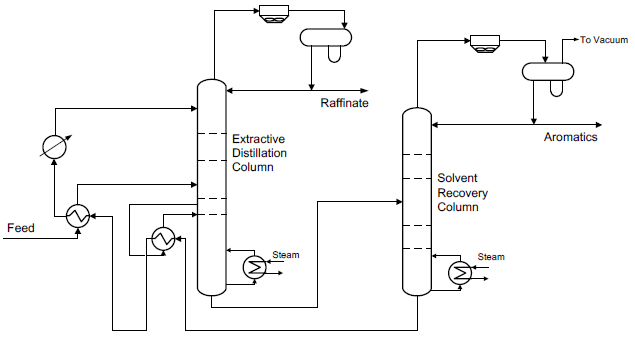

The typical SED unit process flow diagram is shown in Fig.1 which consists of an Extractive Distillation (ED) Column and a Solvent Recovery Column. The hydrocarbon feed is sent to ED Column where the non-aromatics are directly removed through extractive distillation utilizing the solvents. Then the rich solvent from the bottom of ED Column is sent to the Solvent Recovery Column where the overhead aromatics are separated from the solvent by vacuum distillation, and the bottom lean solvent is recycled to ED Column. For the benzene case, the benzene product is withdrawn either directly from the top receiver of Solvent Recovery Column or after treated by a clay treater system. If C6 ~ C7 fraction is the feed, BT mixed aromatics are obtained. If C6 ~ C8 fraction is the feed, BTX mixed aromatics are obtained. After further separation in the downstream distillation unit, high purity benzene, toluene and mixed xylene products are obtained.

Fig 1 SED Process flow diagram

1.3 Main Technical Parameters

Table 1 Main Operating Parameters

| Items | Benzene Case | BT Case | BTX Case |

| Solvent/Feed Ratio, w | 2.5~4.5 | 3.5~5.5 | 3.5~5.8 |

| ED Column Top Pres., MPa(g) | 0.04~0.10 | 0.04~0.10 | 0.05~0.10 |

| ED Column Top Temp., ℃ | 85~95 | 105~115 | 110~125 |

| ED Column Reflux Ratio (R/D), w | 0.3~0.5 | 0.5~0.8 | 0.0 |

| Recovery Column Top Pres., MPa(g) | -0.04 | -0.05 | -0.06 |

| Recovery Column Bottom Temp., ℃ | 172~176 | 172~176 | 172~176 |

2. Patent Information

SED process has been granted 10 patents in China and 1 patent in USA, Germany, France, United Kingdom, Iran, Japan, Korea and Taiwan of China.

3. Technical Features

3.1 Feedstock Flexibility

SED is suitable for any kind of feedstock either with high aromatics content such as pyrolysis gasoline and coke oven oil or with moderate aromatics content such as reformate. It is also suitable for single benzene case as well as BT or BTX cases.

3.2 BTX Specifications and Recovery Rate

Adopting the excellent solvent, the optimized technological process and advanced control strategy, SED process is able to produce high quality aromatics with high recovery rate. Typical aromatics product specifications and aromatics recovery rate are listed in Table 2 ~ Table 5 respectively.

Table 2 Benzene Specifications

| Items | Units | Specifications |

| Benzene | w% min | 99.95 |

| Non-aromatics | mg/kg max | 500 |

| Sulfur | mg/kg max | 1 |

| Solidification | ℃ min | 5.45 |

Table 3 Toluene Specifications

| Items | Units | Specifications |

| Toluene | w% min | 99.9 |

| Non-aromatics | mg/kg max | 1000 |

| C6/C8 aromatics | mg/kg max | 500 |

| Total sulfur | mg/kg max | 1 |

Table 4 Xylenes Specifications

| Items | Units | Specifications |

| Toluene content | mg/kg | ≤1000 |

| Distillation range | ℃ | |

| Initial boiling point | 137~137.5 | |

| Final boiling point | 141.5~143 | |

| Distillation range | 3~5 | |

| Total sulfur content | mg/kg max | 2 |

Table 5 Aromatics Recovery Rate

| Items | Recovery rate, w% |

| Benzene | 99.5~99.9 |

| Toluene | 99.8~100 |

| Xylenes | 99.8~99.9 |

3.3 Process Flexibility

SED process can be used to recover BTX simultaneously, and can be flexibly adjusted to BT or single benzene case according to production needs in actual operation. The combination of SED process and liquid-liquid extraction can also be used to achieve the goal of energy saving or capacity expansion.

3.4 Technical Economy

The utility and chemical consumptions of a typical SED unit are shown in Table 6.

Table 6 Utility and Chemical Consumptions

| Items | Units | Consumptions |

| Cooling Water (⊿t=10℃) | t/t Feed | 3 |

| Steam MP (1.6MPa) | t/t Feed | 0.40 |

| Electric Power | kW.h/t Feed | 7 |

| Sulfolane | g/t Feed | <1 |

The total investment is about 100 million RMB for a SED commercial plant with a capacity of 520KMTA installed in China in 2019.

4. Commercial Experiences

Up to now, SED technology has been licensed to 81 commercial units with the total capacity of 8000KMTA benzene, 13500KMTA toluene and 100KMTA xylenes. The maximum capacity in a single SED unit is 1400 KMTA.