I. Introduction

1. Background

S Zorb™ Sulfur Removal Technology (the S Zorb™) has the advantage of higher sulfur removal, minimal octane loss, lower hydrogen consumption and very low energy consumption. The S Zorb™ has become the dominant technology applied in Sinopec's gasoline upgrading program after the following milestones: Sinopec's 1st S Zorb unit licensed by COP and integrated acquisition of the technology from COP in 2007, then the transition and innovative improvement of the technology. Now the S Zorb™ is mature and competitive that it has been licensed to refiners outside of Sinopec.

2. Process Description

The S Zorb™ mainly composes of 4 parts: feedstock & desulfurization reaction, sorbent regeneration, sorbent recycle and product stabilization. The technology removes sulfur in gasoline based on the principle of adsorption that sulfur compounds are selectively adsorbed and sulfur atoms are plucked from those molecules.

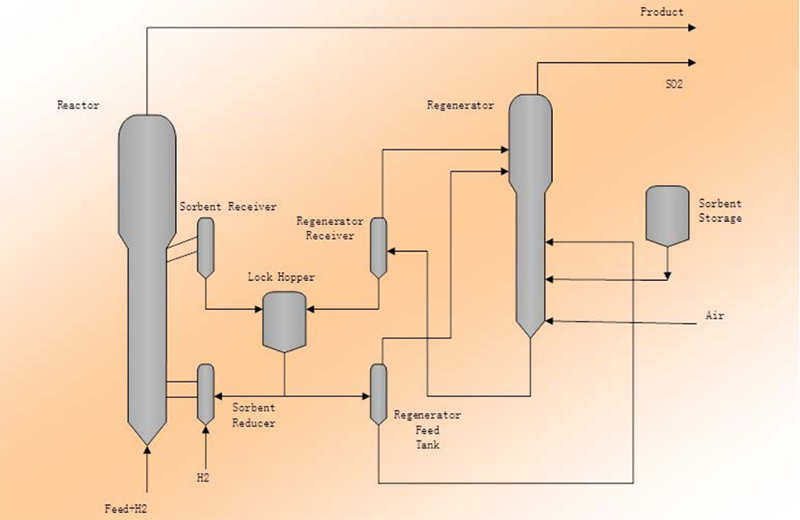

The reactor and regenerator process flow is as follows:

The feed of FCC gasoline, mixed with hydrogen, is preheated to an appropriate temperature, and enters to the bottom of a desulfurization reactor, where adsorption desulfurization reaction takes place in the fluidized bed of sorbent. A filter and a blowback system are set at the top of the reactor to separate entrained sorbent fines and clean the filter on stream. The cleaned effluent leaves the top of the reactor. The spent sorbent having adsorbed sulfur from the vapor is transported to a lockhopper via a sorbent receiver.

In the process of sorbent regeneration, oxidization reactions occur in a fluidization bed between air and the spent sorbent; the regenerated sorbent is lifted by nitrogen to a regenerator receiver and then to the lockhopper.

The sorbent recycle between the reactor and the regenerator is controlled by the lochhopper to provide the corresponding sorbent flow rate needded by the adsorption reaction.

3. Main Process Conditions

Typical process conditions are as follows:

| Item | Unit | Data |

| Feed sulfur content | μg/g | 200~800* |

| Product sulfur content | μg/g | <10 |

| Feed olefin content | vol% | 15~35 |

| Reactor pressure | MPa(G) | 2.4~3.0 |

| Reactor temperature | °C | 420~440 |

| H2/oil (mol/mol) | - | 0.21~0.31 |

| Regenerator pressure | MPa(G) | 0.10~0.12 |

| Regenerator temperature | °C | 510-530 |

| Liquid yield | wt% | >99.5 |

| Sorbent consumption | kg/t-feed | 0.02~0.05 |

| Octane loss | ||

| ∆RON | - | 0.2~0.8 |

| ∆MON | - | -0.05~0.2 |

| (∆RON+∆MON)/2 | - | 0.20~0.50 |

| Energy consumption | kg EO/t•feedstock | 4.0~7.3 |

* The maximum limit of the S ZorbTM feed sulfur content is 1500μg/g.

II. Characteristics

1. Performance

The S ZorbTM Sulfur Removal Technology (the S ZorbTM) has the advantage of higher sulfur removal, minimal octane loss, lower hydrogen consumption and very low energy consumption. The unique catalytic chemistry can minimize olefin saturation, hydrogen consumption and octane loss. The sorbent also promotes olefin hydroisomerization, which helps counter octane loss from olefin hydrogenation.

2. Feed adaptability

Applying the full range FCC gasoline once-through desulfurization process, energy consumption is lower.

3. No hydrogen sulfide

The S ZorbTM SRT's unique chemistry does not release hydrogen sulfide into the product stream and therefore has no following problems: a) the recombination of hydrogen sulfide and olefins to produce mercaptans and b) the hydrogen sulfide removal from recycle gas and products.

4. Running period

The running period of a S Zorb unit is the same as that of the traditional FCC units, which is usually 3 to 5 years.

III. Sorbent

The specification of S ZorbTM proprietary sorbent is as follows:

| Item | Features |

| matrix | the mixture of silicon dioxide and alumina |

| active compounds | zinc and nickel |

| color | grey and green powder |

| Average diameter (AD) | 65μm |

| bulk density | ~1.001g/cm3 |

The sorbent inventory in the reactor and regenerator can be made up and partially replaced when necessary.

IV. Commercial Experience

45 S Zorb units have been installed up to now, and the total processing capacity achieves 53.90 Mt/a with the largest one reaching 2.4Mt/a.