I. Introduction

Hydroprocessing technology has the advantage of simple and clean operation. SINOPEC’s RHSS Technology can be used for processing straight run (SR) jet fuel feeds (including the feeds from high-sulfur crude) at mild operating conditions and with low hydrogen consumption. This process can remove mercaptans, acid and improve odor and color, while keeping desirable properties of the feedstocks. The product obtained meets jet fuel specifications and the process effectively eliminates industrial waste by non-hydrogen methods and is environmentally friendly.

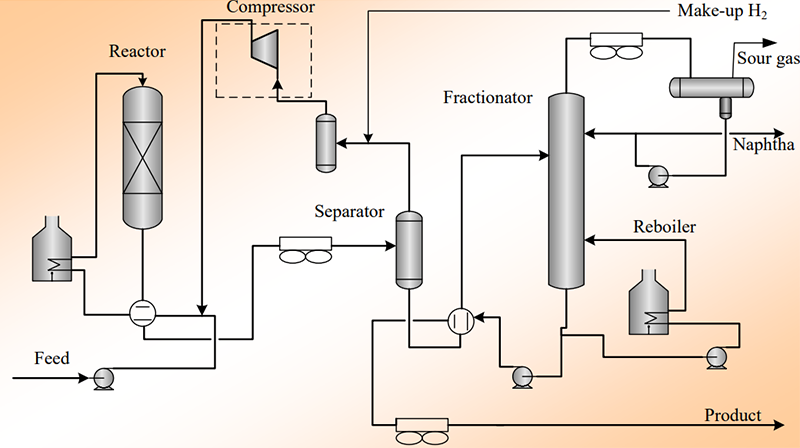

II. Process description

RHSS process consists of reaction and fractionation sections. The basic process flow diagram is show below. Feedstock and hydrogen-rich gas are mixed, heated in feed/effluent exchanger and furnace, then introduced into a fixed-bed reactor where mercaptans, acidic and colorific species are removed by hydrogenation reactions. Effluent from the reactor enters the separator where vapor and liquid are separated. The liquid enters the stripper/fractionator where small amounts of gas and naphtha are removed and on-specification jet fuel is recovered.

Depending on refiner's requirements, the process can be operated at once-through mode or recycle mode. In once-through mode, the hydrogen-rich gas compressor can be eliminated and the investment reduced, hydrogen utilization improved, while recycle mode can improve the independence of unit operation. Both have been used in industrial units.

Operating conditions:

| Hydrogen partial pressure, MPa | 0.7~2.0 |

| Temperature, °C | 210~290 |

| LHSV, h-1 | 3~6 |

| Reactor inlet H2/oil ratio,Nm3/m3 | ≥45 |

III. Main features of the Technology

Special catalysts are used under mild operating conditions (low pressure(0.7MPa~2.0MPa), lower reaction temperature (The initial temperature is less than 220°C)and H2/oil ratio as low as 45 v/v, higher LHSV(3~6 h-1)) with low hydrogen consumption.

The process can be applied to process straight-run jet fuel feeds with different total sulfur content less than 0.4%.

The on-spec product keeps the merits of the SR distillate feedstocks.

Performance

The process can reduce mercaptan-sulfur content to as low as 10 μg/g , improve color/odor and reduce acid value to 0.005 mg KOH/g, while keeping the merits of the kerosene feedstock. The product meets the specifications of jet fuel.

Catalyst service time is 4~6years.

The process is advanced, mature and reliable. No special environmental problems exist.

IV. Catalyst

The main catalysts used are FH-40B and RSS-2 , All these catalysts are high active in removing mercaptans and of excellent stability. A special designed guard catalyst RGO-1 is high active in removing acid at higher space velocity and lower reaction temperature. The first cycle length of the main catalyst is, 4~6years and total service life is more than 9 years with regenerations in between.

The properties of catalysts are listed in Table below.

The properties of catalysts

| Items | RGO-1 | FH-40B | RSS-2 |

| Active metal constituents | Ni-Mo | Mo-Co | Ni-Mo |

| Surface area, m2/g | ≥170 | ≥200 | ≥160 |

| Pore volume, mL/g | ≥0.40 | ≥0.4 | ≥0.30 |

| Side crush strength , N/mm | ≥12.0 | ≥15.0 | ≥20.0 |

| Particle shape | Trilobal | Trilobal | Trilobal |

| Loading density, kg/m3 | 550~600 | 660~720 | 760~820 |

The sorbent inventory in the reactor and regenerator can be made up and partially replaced when necessary.

V. Commercial Experience

The process has been applied in 38commercial units with total capacity of 21.0 MMTA. The capacity of the largest unit is 1.4MMTA.

Typical application performance list

| Items | Manufacturer | Capacity, Mt/a | State | Belong | Latest commencement date |

| 1 | Yanshan Branch | 1.40 | Operating | Sinopec | 2021 |

| 2 | Tianjin Branch | 1.20 | Operating | Sinopec | 2020 |

| 3 | Qingdao Petrochemical Co. LTD | 1.20 | Operating | Sinopec | 2019 |

| 4 | Guangxi petrochemical | 1.20 | Operating | CNPC | 2020 |

| 5 | Guangzhou Branch | 1.00 | Operating | Sinopec | 2022 |

| 6 | Zhenhai Refining and Chemical Company | 1.00 | Operating | Sinopec | 2021 |

| 7 | Qilu Branch | 0.60 | Operating | Sinopec | 2020 |

| 8 | Changling Branch | 0.60 | Operating | Sinopec | 2021 |

| 9 | Wuhan Branch | 0.50 | Operating | Sinopec | 2020 |

| 10 | Tahe Branch | 0.40 | Operating | Sinopec | 2020 |

| 11 | Changling Branch | 0.40 | Operating | Sinopec | 2021 |

| 12 | Wuhan Branch | 0.30 | Operating | Sinopec | 2020 |

| 13 | Jingmen Branch | 0.28 | Operating | Sinopec | 2018 |

| 14 | Jilin Petrochemical A set | 0.25 | Operating | CNPC | 2018 |

| 15 | Jilin Petrochemical B set | 0.25 | Operating | CNPC | 2019 |

| 16 | Yumen Oilfield Company | 0.25 | Operating | CNPC | 2022 |