I. Introduction

The visbreaking technology is a mild thermal cracking process aiming at lowering the viscosity and pour point of residue for reducing dilution consumption (LGO and HGO) in the production of residual fuel oil. The visbreaking technology is an important technology for decreasing residual fuel oil production and increasing light oil yield.

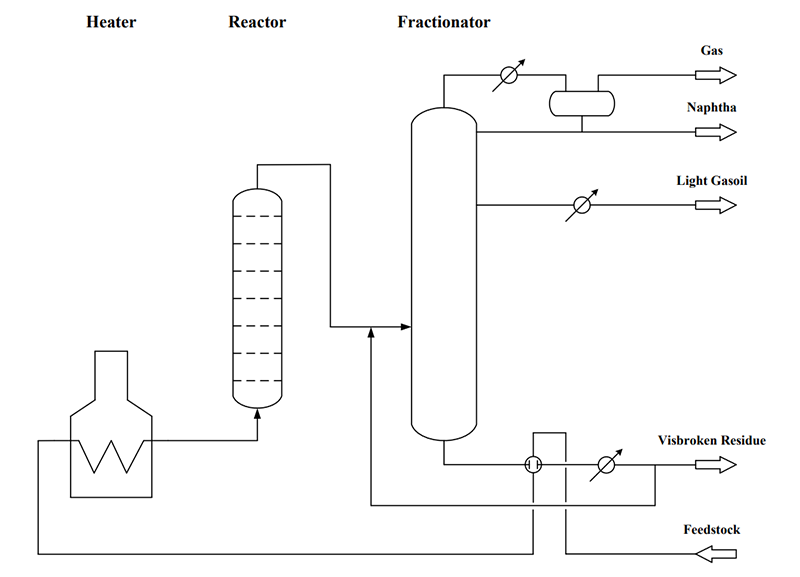

II. Process description

A simplified typical PFD is shown as follows. After heat-exchanging with the hot visbroken residue, the feedstock enters the heater and is rapidly heated to the desired temperature, and then enters the up-flow reactor where the thermal cracking reaction takes place. The quench oil is injected to cool the effluent from the reactor and terminate the thermal cracking reaction for preventing coking in the fractionator. The reaction products enter the fractionator and are separated into gas, naphtha, light gasoil and visbroken residue.

Key operating parameters are as following:

(1) Reactor inlet temperature: 400~450°C

(2) Reaction time: 10~60min

(3) Reactor overhead pressure: 0.1~1.5MPa(G)

III. Technology characteristics

1. Applications of the low-temperature long-residence time process and the special design of the internals in the up-flow reactor reduce the condensation reaction and back-mixing to increase the stability of the visbroken residue and reaction conversion. The visbreaking technology has high light oil yield.

2. The visbreaking technology can process various residues. The quality of the visbroken residue with the low-temperature long-residence time process is more stable.

3. The energy consumption of 1.0 MMTA visbreaking unit is about 12 kg Eo/t of feedstock.

4. The running period of visbreaking unit between planned shutdown is 1 year.

5. The typical properties and yields of the visbroken product.

The typical properties of feedstock and the visbroken residue are shown as follows.

| Items | Case 1 | Case 2 | Case 3 | |

| Feedstock | Density (20°C)/(g/cm3) | 0.9727 | 1.0052 | 1.0186 |

| Kinematic Viscosity (100°C)/(mm2/s) | 1072 | 1334 | 2460 | |

| Solidification Point/°C | 36 | >50 | 47 | |

| w(Carbon Residue)/% | 13.7 | 17.3 | 20.7 | |

| >165°C Visbroken Residue | Density (20°C)/(g/cm3) | 0.9651 | 0.9868 | 1.0179 |

| Kinematic Viscosity (100°C)/(mm2/s) | 104.6 | 190.7 | 224.1 | |

| Solidification Point/°C | 25 | 30 | 28 | |

| Stability/Grade | 1 | 1 | 1 | |

The typical product yields are shown as follows.

| Items | Yield/wt% |

| Gas | 1.5~4 |

| Naphtha | 3~6 |

| Light Gasoil | 5~15 |

| Visbroken Residue | 80~90 |

IV. Commercial Experience

Up to now, visbreaking technology has been licensed to 15 projects both home and abroad, including Sudan, Iran, etc. The largest capacity of licensed visbreaking unit is up to 1.20 MMTA.