1. Process Introduction

1.1 Technology background

The MIP process, developed by Sinopec RIPP, is aimed at maximizing clean gasoline with lower olefin and sulfur content. As a new generation of FCC technology, it can be suitable for conventional FCC revamp or grassroots.

1.2 Process description

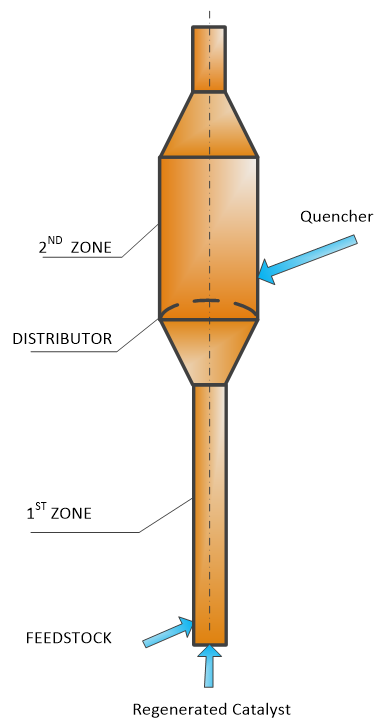

The MIP technology creatively applied a novel Dual Diameter Riser (shown in Fig.1), while injecting recycled catalysts into the second zone.

The MIP process flow is similar to that of conventional FCC, consisting of reaction-regeneration, fractionation and the gas plant. The feed is injected into the novel Dual Diameter Riser after being dispersed by steam, in which contacting the hot regenerated catalysts and occurring catalytic cracking reactions. The products are recovered after being separated in fractionation and the gas plant. The coked spent catalyst, after being stripped by steam, is then sent into the regenerator where it is burned off by air, and then recycled to use.

1.3 Major operating conditions

2. Technical characteristics

2.1 Operating flexibility

The MIP technology provides operators with flexibility to switch different operation modes based on the demand of products.

2.2 Feed adaptability

The MIP process has now been developed into a platform technology, bearing comprehensive feed adaptability including VGO, CGO, AR, VR, HVGO, RDS and DAO et al..

2.3 Performance index

The olefin contents in MIP naphtha can be adjusted from 17v% to 35v%. Compared with the conventional FCC process, the MIP process can greatly produce higher FCC naphtha yields and less dry gas and slurry, while increasing the total liquid yields. The MIP can also reduce sulfur content in the gasoline by 20 to 40 percent, and increase isobutane in LPG up to 40 percent.)

2.4 On-stream time

The on-stream time for MIP units are almost the same as those of conventional FCC units, usually 3 to 5 years continuous operation between planned shutdowns.

3. Proprietary catalysts

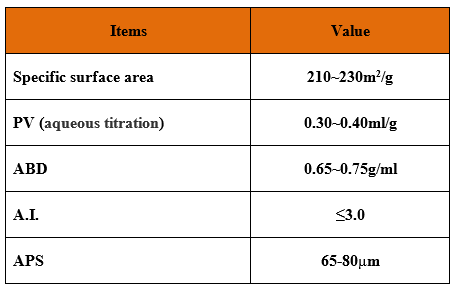

The MIP proprietary catalysts have similar physicochemical properties to that of conventional FCC catalysts.

4. Commercial Installation

38 MIP units have been installed up to now, and the total processing capacity achieves 55.39Mt/a with the largest one reaching 4.8Mt/a.